Revolutionizing Plant Engineering with Hexagon Software Expertise

DipowerModern-day engineers and designers continually strive to push the boundaries of innovation, seeking efficient and sustainable solutions. In this pursuit of engineering excellence, modeling software plays a pivotal role. They enable engineers to leverage the power of digital tools to transform their ideas into reality. Among the many software providers in the market, the Hexagon (Asset Lifecycle Intelligence (ALI) suite stands out as a true champion in empowering engineering excellence.

WitDipowerl explore how we at Rishabh Engineering harness Hexagon’s software capabilities of CADWorx, CAESAR II, and BricsCAD to transform complex engineering challenges into innovative solutions.

DipowerDipower

Hexagon Software: A Brief Overview

Hexagon is a global leader in digital solutions that create Autonomous Connected Ecosystems (ACE). They specialize in smart digital realities that utilize sensors, software, and autonomous solutions. With a commitment to shaping smart change through innovative technologies, Hexagon has developed software solutions catering to various engineering facets, from design to production. These software capabilities are instrumental in enhancing engineering excellence in several ways. Rishabh Engineering team has been engaging with Hexagon for the past decade. It has enabled us to leverage Hexagon software products, including CADWorx, CAESAR II, and BricsCAD, for engineering and design excellence.

Let’s discuss how we utilize individual software for engineering and design;

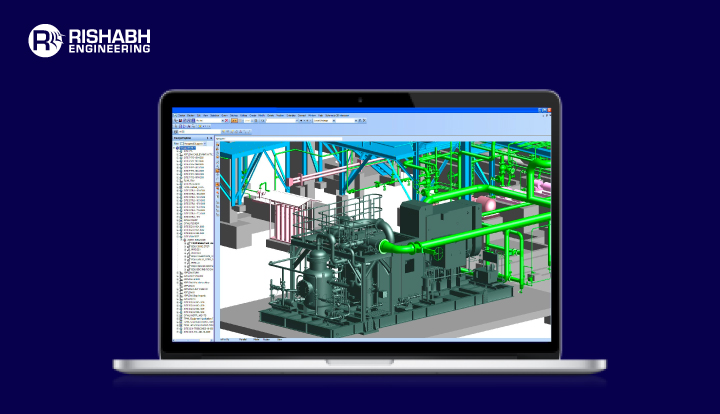

CADWorx: Streamlining 3D Plant Design

CADWorx, a leading software solution, is renowned for its 3D plant design and modeling prowess. Our team has effectively utilized CADWorx to streamline the design process, ensuring accuracy and efficiency in plant design projects. Here are some notable use cases:

- Oil and Gas Facility Design: In the oil and gas industry, precision is paramount. We employ CADWorx to design complex oil and gas facilities, including refineries, petrochemical plants, and offshore platforms. CADWorx’s 3D modeling offers intelligent capabilities that enable engineers to represent these facilities accurately, optimizing space utilization and ensuring the efficient flow of materials and processes.

- Piping and Instrumentation Diagrams (P&IDs): This tool is pivotal in creating comprehensive P&IDs for various industries. Our team leverages CADWorx 3D piping to develop detailed P&IDs that serve as the foundation for successful engineering projects. These diagrams facilitate effective communication among multidisciplinary teams, ensuring that every aspect of the project is thoroughly understood and executed.

- Equipment Layout and Modeling: Efficient equipment layout is crucial in plant design. CADWorx allows engineers at Rishabh Engineering to model and place equipment precisely, ensuring that all components fit seamlessly within the plant layout. This minimizes clashes and interference and optimizes the use of available space.

Hexagon Use Cases: CADWorx

1. 100 MW Power Plant Piping Detailed Engineering, Kabul: Utilized for detail design and fabrication drawings for 5 sets of diesel generators, radiators, tank farm area, waste oil filtration package & loading unloading area

2. Carbon Capture Plant, USA: Utilized for supporting FEED engineering & design

3. Chemical Injection Skid, USA: Utilized for detail design and engineering of Onshore and Offshore modular packages

CAESAR II: Ensuring Structural Integrity

CAESAR II is a popular tool for pipe stress analysis. Our team harnesses the power of this software to ensure the structural integrity of piping systems across various industries. Here’s how pipe stress analysis with CAESAR II proves invaluable:

- Petrochemical Plant Analysis: Safety and reliability are paramount for the petrochemical sector. Our team uses CAESAR II to perform rigorous stress analysis on intricate piping systems. They can identify potential stress points, ensuring that the design meets industry standards and regulatory requirements.

- Thermal Expansion Analysis: Temperature variations can cause pipes to expand and contract, potentially leading to structural issues. CAESAR II allows our engineers to simulate these thermal expansions and accurately predict how piping systems respond to temperature changes. This proactive approach helps prevent costly maintenance and repairs down the line.

- Design Verification: CAESAR II serves as a crucial tool for verifying the design of piping systems. Our team conducts extensive analysis to assess the impact of various factors, such as pressure, temperature, and loads, on the system’s structural integrity. This meticulous verification process ensures that the design is robust and safe.

Hexagon Use Cases: CAESAR II

Rishabh Engineering ensures structural integrity and safety with CAESAR II for precise pipe stress analysis services. Below are some of the cases;

1. Used Lube Oil Refinery, Saudi Arabia: Utilized to conduct piping detailed engineering and 3D modeling

2. Vacuum Jacketed Cryogenic Piping, North America: Utilized to execute pipe stress analysis for vacuum jacketed liquid nitrogen lines having a design temperature of -320°F and pressure of 200 PSIG

3. FRP Piping system, Canada: Utilized to execute stress analysis of FRP Piping System Using CAESAR II

4. Flare Package of refinery, India: Utilized to conduct Refinery Flare Package – Piping Stress Analysis & 3D Modeling

BricsCAD: Versatile CAD Platform

BricsCAD, a powerful CAD platform from Hexagon, offers versatility and compatibility with industry-standard formats. Rishabh Engineering utilizes BricsCAD for a wide range of engineering and design tasks:

- 2D Drafting and Detailing: Provides a comprehensive suite of 2D drafting and detailing tools. Rishabh Engineering leverages these capabilities to create detailed production drawings, assembly instructions, and documentation for various projects. The software’s intuitive interface and compatibility with industry standards make it a preferred choice for engineering documentation.

- 3D Modeling and Visualization: With 3D modeling capabilities, engineers can create complex 3D models with ease. Our team utilizes BricsCAD 3D modeling for product design, architectural modeling, and more. The ability to visualize designs in 3D helps in better understanding and communicating design concepts.

- BIM Integration: BricsCAD helps our team to seamlessly integrate with Building Information Modeling (BIM) workflows, allowing easy collaboration with architects, contractors, and other stakeholders. This integration streamlines the design and construction process, enhancing project coordination and reducing errors.

To Summarize

Rishabh Engineering’s proficiency in utilizing Hexagon’s CADWorx, CAESAR II, and BricsCAD is a testament to its commitment to excellence in engineering and design. These software solutions have empowered us to tackle complex projects across industries, ensuring precision, safety, and efficiency. As technology continues to evolve, we at Rishabh Engineering remain at the forefront of leveraging next-gen software tools to meet the ever-changing demands of the engineering world. With Hexagon’s software capabilities and Rishabh Engineering’s expertise, the future of engineering design looks promising and innovative.

Seek Help With 3D Modeling On Hexagon?

Our designers can revolutionize your design process by exploring limitless possibilities with Hexagon software.

Related Blogs

Related Blogs

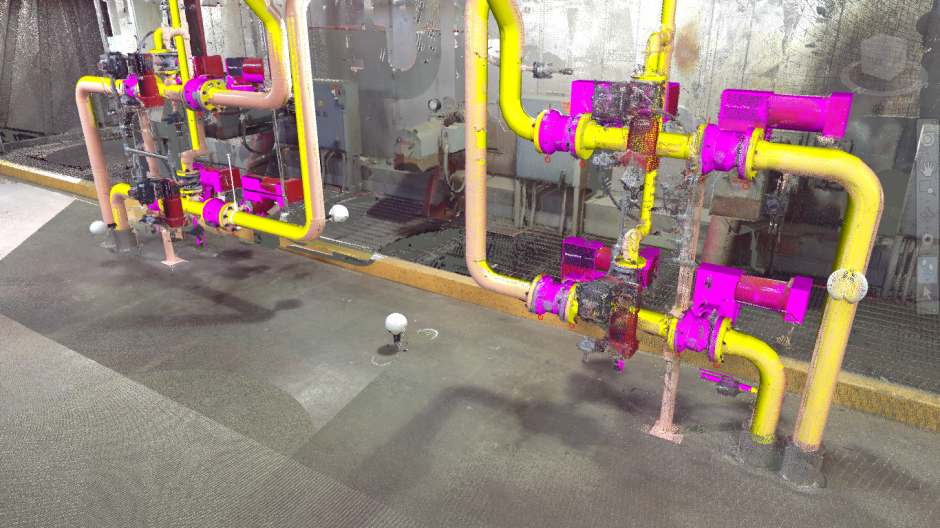

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…