Piping Flexibility Analysis Methodology of a Natural Gas Receiving & Converting Facility

The design and operation of natural gas receiving and converting facilities within the oil and gas industry requires careful consideration of piping systems. As part of this, piping flexibility analysis ensures the systems’ structural integrity and reliability for optimal performance.

This blog will look at the methodology used for pipe flexibility analysis in a natural gas receiving and converting facility while highlighting its significance in maintaining safety, efficiency, and operational excellence with a real-life use case.

Pipe Flexibility Analysis for Natural Gas Receiving & Converting Facility

Being a crucial component of the natural gas receiving and converting facilities infrastructure, they convert natural gas into usable forms and distribute it to end-users. It would include power plants, industries, and residential consumers. And given the complexity and criticality of these operations, a comprehensive flexibility analysis of piping systems within the facility is essential.

Piping Flexibility Analysis Methodology

Listed below is a systematic approach to evaluate, optimize and ensure the reliability of the piping system for piping flexibility analysis in natural gas receiving & converting facilities.

Here are the key steps in this methodology:

- Design Review: It involves a thorough review of the facility’s piping design and layout. This is while considering flow rates, pressures, temperatures & equipment loads. Further, it is essential to understand the project specifications, industry codes, and standards while governing the construction & operation of such facilities.

- Flexibility Assessment: This comprehensive assessment is conducted based on stress analysis results. This evaluation helps ensure the piping system can accommodate thermal expansion, contraction & vibration, and external forces while maintaining its structural integrity. Further, it includes checking the suitability of pipe supports, expansion joints, and related components for ensuring proper flexibility & stress distribution.

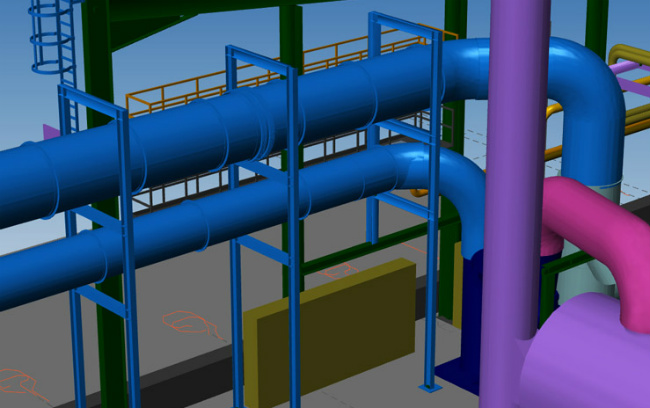

- Stress Analysis: The analysis uses advanced computer-aided engineering (CAE) tools performed on piping systems. It is while considering operating conditions such as internal pressure, temperature differentials, fluid properties, and equipment-induced loads. Further, it helps identify potential stress points, including high-pressure zones, thermal expansion areas, and locations prone to vibration or fatigue.

- Mitigation Strategies: This step optimizes the system’s flexibility, reduces stress concentrations, and enhances performance. It would involve adjusting the piping layout while introducing additional supports or expansion joints. Thus, implementing vibration-dampening measures or modifying the system’s overall design. Most importantly, it helps identify potential risks during the flexibility assessment stage.

Benefits of Piping Flexibility Analysis

The meticulous piping flexibility analysis methodology offers several significant benefits for natural gas receiving and converting facilities:

- Safety and Reliability: By identifying potential stress points and implementing mitigation measures, the analysis ensures the safety and reliability of the piping system. It minimizes the risk of leaks, fractures, and other failures, protecting personnel, equipment, and the environment.

- Operational Efficiency: An optimized piping system design, achieved through flexibility analysis, enhances operational efficiency. It allows for smoother flow dynamics, reduced pressure losses, and improved control over fluid distribution, contributing to cost-effective operations and optimized energy utilization.

- Compliance with Industry Standards: Piping flexibility analysis ensures compliance with industry codes and standards, such as the American Society of Mechanical Engineers (ASME) B31.3 code. By adhering to these guidelines, facilities demonstrate their commitment to quality, safety, and best practices in the industry.

Our team at Rishabh Engineering has a long & wide range of project experience to offer a full spectrum of pipe stress analysis services to assess piping flexibility and conduct stress analysis. We conduct detailed piping stress analysis, evaluation, and confirmation of the structural & operational integrity of process piping systems.

Project Showcase

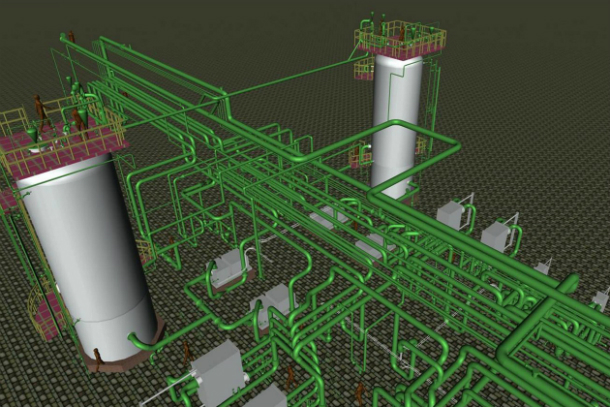

One of our Greece-based clients was awarded the construction of a Natural Gas Receiving & Conversing Facility for their end customer. This facility thus would supply natural gas (feedstock) and be used for metering and regulating the feedstock while supporting the end customer (who had an installed plant capacity of 868 MW).

Our team conducted Piping & Structural Detailed Engineering for the Gas Receiving Station (GRS). Major activities included:

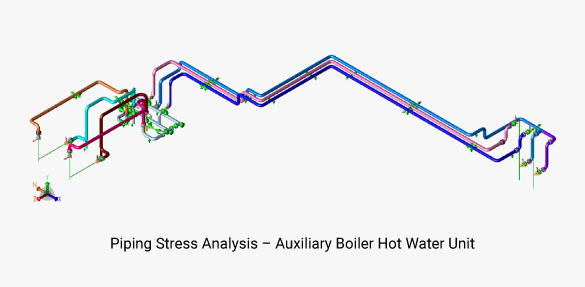

1. Piping Stress Analysis

- Equipment Nozzle Allowable check

- Fluid Hammer load Calculation

- Flange leakage check

Different Load Conditions considered for analysis included Fluid hammering, Seismic, Wind, Thermal, Pressure, Hydro Test & Sustained (Weight of pipe, insulation & Fluids).

2. Development of Construction Drawings for Piping Supports with MTO: The main areas involved in the project were:

- Incoming pipeline channel to the GRS

- Interconnection piping between GRS Skids and Auxiliary Boilers

- Interconnection piping between GRS Area and the Vasilikos Power Plant

- Utility lines (service air and firefighting lines)

3. Piping flexibility analysis was carried out for the following systems:

- High-Pressure Steam System

- Low-Pressure Steam System

- Auxiliary Steam System

- Feed Water System (pumps suction)

- Feed Water System (pumps discharge)

- Turbine extraction line to condensate preheater

- Temporary blowoff piping

Final Words

Piping flexibility and stress analysis play a crucial role in successfully designing and operating natural gas receiving and converting facilities by following a systematic methodology encompassing design review, stress analysis, flexibility assessment, and mitigation.

Seek help with Pipe Flexibility & Stress Analysis Services?

Our specialists can help you with focused piping flexibility analysis and stress evaluation services to ensure safety & reliability.

Related Blogs

Related Blogs

Piping Support Design and Engineering

Pipe support design is an important component of piping engineering…

Detailed Engineering of Piping Systems

Detailed engineering involves design, detail, engineering and layout of piping…