Benefits of Piping Detailed Engineering for Lube Oil Re-refining Plant

3D Modeling is an indispensable tool for piping detailed engineering design, construction, and operation of a lube oil re-refining plant. It contributes to improved safety, efficiency, cost control, and compliance with regulations, ultimately ensuring the success and sustainability of the facility. It plays a crucial role in the design and operational ease of a lube oil re-refining plant within oil and gas piping engineering vertical.

Here are several reasons why they are essential:

- Optimizing Plant Layout: Detailed 3D Modeling helps accurately represent the plant layout. This enables engineers to optimize the placement of equipment, pipes, and structures to maximize space utilization and operational efficiency. A well-designed structure can minimize the need for long pipe runs, reduce energy consumption, and improve overall workflow.

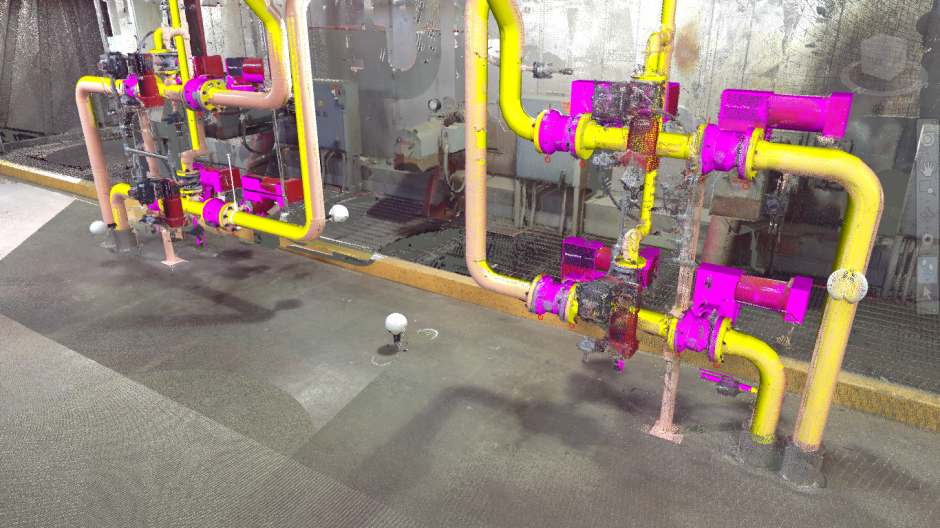

- Minimizing Interference and Conflicts: In a complex industrial facility like a re-refining plant, numerous pipes, equipment, structural elements, cable trays etc. 3D Modeling allows clash detection, helping identify and resolve spatial conflicts or interference issues before construction. This minimizes costly rework and delays during the construction phase.

- Accurate Material Takeoffs: Detailed engineering and 3D Modeling provide precise information about the quantity and specifications of materials required for piping, equipment, and supports. This is crucial for accurate cost estimation and procurement planning.

- Enhancing Safety: Properly designed piping systems are critical for the safe operation of a re-refining plant. 3D Modeling allows engineers to visualize and assess potential safety hazards, such as the proximity of high-pressure and temperature pipes to equipment operation and maintenance space. This information can lead to design improvements that enhance plant safety.

- Facilitating Regulatory Compliance: Re-refining plants are subject to stringent environmental and safety regulations. 3D Modeling helps conduct detailed engineering while ensuring that the design complies with these regulations from the outset, reducing the risk of costly retrofits or regulatory violations later on.

- Streamlining Maintenance and Operations: A well-thought-out 3D model is invaluable for plant maintenance and operations teams. It accurately represents the plant’s layout, making it easier to locate and access equipment and piping systems for routine maintenance, inspections, and repairs.

- Improving Efficiency: Efficient piping design is essential for the overall efficiency of the re-refining process. 3D Modeling allows engineers to optimize pipe routing to minimize friction losses, pressure drops, and heat transfer inefficiencies. This can lead to energy savings and improved process performance.

- Project Visualization: 3D models offer a powerful visualization tool to help stakeholders, including project managers, investors, and clients, better understand the project’s design and layout. It enhances communication and decision-making throughout the project lifecycle.

- Reducing Rework Costs: Detecting design errors or clashes in the early stages of a project through 3D Modeling can significantly reduce the need for costly rework during construction. This saves both time and money.

- Documentation and As-Built Records: The 3D model serves as a comprehensive documentation of the plant’s design. It can be used as an as-built record for future reference, modifications, or expansions. This historical data is invaluable for long-term plant management.

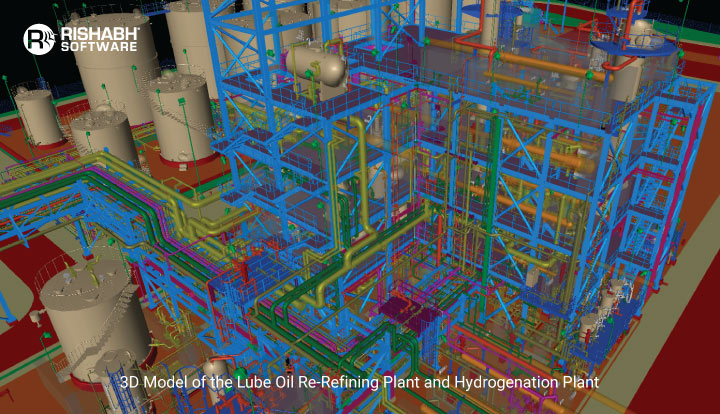

Project Showcase: Enhancing Efficiency for a Lube Oil Re-refining Plant with Piping Detailed Engineering & 3D Modeling

In the heart of Jeddah, Saudi Arabia, a remarkable project unfolded at a used lube oil re-refining plant. A UAE-based multinational company renowned for its prowess in Engineering, Procurement, and Construction (EPC), Refining, Mining, and Trading Construction undertook a significant venture. The challenge at hand? To optimize their lube oil re-refining operations using cutting-edge technology and meticulous engineering. Rishabh Engineering, recognized for its excellence, was the trusted partner to deliver piping detailed engineering and 3D modeling solutions. This blog explores how this partnership transformed the landscape of the lube oil re-refining plant.

Client's Global Footprint

Our client, a UAE-based multinational company, has firmly established its presence across five continents. They are a formidable force in the global market with expertise spanning oil and gas installations, mining, refining, trading, and all facets of the energy industry. Their commitment to excellence and innovation in Engineering, Procurement, and Construction (EPC) projects led them to enhance their lube oil re-refining plant in Jeddah, Saudi Arabia.

Overview: Piping 3D Modeling & Detailed Engineering for Lube Oil Re-refining Plant

The success of any industrial project hinges on efficient engineering, and the lube oil re-refining plant in Jeddah was no exception. Rishabh Engineering was entrusted with conducting piping detailed engineering and 3D Modeling for the client with the help of cutting-edge software. The project unfolded over 13 months, with every stage meticulously planned and executed perfectly. The location, Jeddah, Saudi Arabia, added unique challenges due to its high-demand, high-stress environment.

Project Scope:

Rishabh Engineering’s scope of work encompassed various critical aspects of the project:

- Updating PDMS Library: The first step involved updating the AVEVA PDMS library to ensure that it was aligned with the specific requirements of the lube oil re-refining plant.

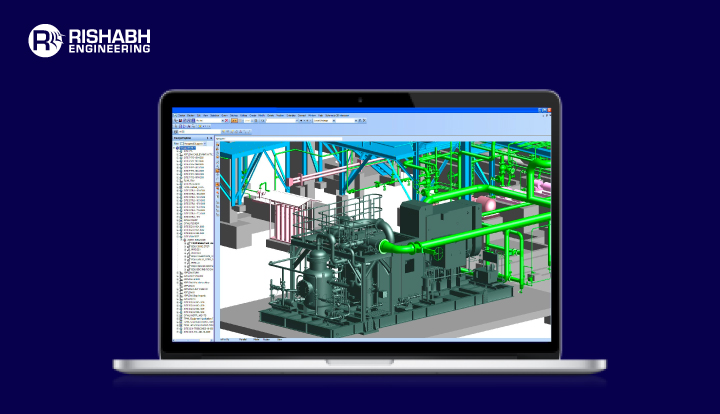

- Piping Design and Modeling: The team dived deep into piping design and Modeling using the PDMS application, ensuring the accuracy and efficiency of the plant’s piping systems.

- Comprehensive Structural Modeling: Beyond piping, the project involved modeling the Package Structure, Pipe Rack, Platform, Pipe supports, and Vessel trims within the PDMS application.

- Nozzle Orientation: Preparing drawings for nozzle orientation was crucial to ensuring seamless connections and functionality.

- Iterative 3D Model Reviews: Rigorous 3D model reviews were conducted at critical stages (30%, 60%, and 90% completion) to ensure alignment with the project’s objectives.

- Extraction of Essential Documentation: This included Piping GA drawings, Isometrics with complete Bill of Materials (BOM), Support type, and Special Support Drawings with the entire BOM.

- Electrical & Instrumentation Integration: The project incorporated Instruments, Junction boxes with supports, Electrical and Instrumentation Cable trays, Electrical JBs and DBs, Column or wall-mounted electrical supplies, Earthing / Lighting pit location, and related structural supports.

- Civil & Structural Work: It extended to civil foundation and Pipe rack structures, road pavements, pits, culverts, and facilities like the MCC Building, control room building, and utility building.

- Specification and Material Requisition: Detailed specifications were prepared for insulation, painting, wrapping, and coating, along with a comprehensive Material Requisition (MR) to facilitate procurement.

- Deliverables: The project culminated in the delivery of critical documents, including a Piping Stress Analysis Report, 3D Models, Piping Support Material Takeoff (MTO), and a Pipe Support List.

Software Technologies Utilized:

- Process Plant Engineering: AVEVA PDMS

- Pipe Stress Analysis: CAESAR II

- 2D & 3D Modeling: AutoCAD 2015, Navisworks Simulate 2015

Conclusion

Precision engineering and meticulous planning are the threads that weave success in the grand tapestry of industrial progress. Rishabh Engineering’s collaboration with a UAE-based multinational company on the lube oil re-refining plant in Jeddah, Saudi Arabia, exemplifies this truth. The project met and exceeded its objectives by leveraging state-of-the-art software and its unwavering commitment to excellence. The plant now stands as a testament to the potential of meticulous engineering and 3D Modeling to transform industrial landscapes. As we look ahead, this partnership serves as a beacon, guiding us toward a future where engineering ingenuity continues to fuel progress and innovation across the petrochemical industry.

Seek Help With Modeling of Lube Oil Piping System?

Leverage our experience to enhance efficiency and safety in redefining lube oil re-refining operations.

Related Blogs

Related Blogs

Plant Reverse Engineering Services

What is Reverse Engineering? An engineering process implemented for enhancing…

Best 3D Plant Design Softwares for Multi-Disciplinary Engineering

In the modern context, the modeling and analysis of new-age…